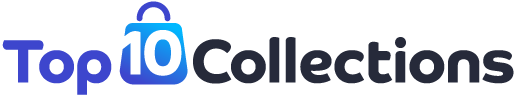

American Black Walnut is a beautiful species with a rich, dark, lustrous heartwood that produces very durable, beautiful furniture and ornaments.

Walnut is also very expensive. You may be able to save a little money by using walnut veneer sheets for your project, rather than solid wood.

If that is your plan, follow these other 6 tips for saving money on your veneer project.

Have a Backup (Even If Your Heart Is Set on One Species)

We get it. You’re in love with the beautiful dark notes of American walnut veneer sheets. You can stick with that species, but you should still have a backup alternative.

Not an alternative species – an alternative cut. For instance, if you’re going to use flat-sawn walnut wood veneer sheets because you love the cathedrals, have two or three backup flat-sawn cuts so that you can match up the grain orientation.

Similarly, have backup choices for quarter-sawn sheets and knotty and burl sheets, the irregular grain structures of each will look more natural together (for instance, knotty and burl, as opposed to flat-sawn and quartersawn, or quartersawn and burl).

Having a few options picked out gives you flexibility in case there is not enough of one specific cut in stock to finish your project.

If You Have Questions, Ask!

Don’t feel as though you need to be a subject matter expert in wood veneer just because you are taking on a veneer project.

The time to ask is before you start, and the supplier from which you plan to buy your veneer sheets can serve as an invaluable resource in the process.

For instance, ask about how the wood veneer in question responds to stains and finishes. Some wood species accept finishes more readily than others; in some species, finishes highlight the grain, in others, they can obscure it.

It is important to be aware of these details so that you can create a sense of continuity among the sheets or panels for the purpose of matching – so if you are unsure, ask.

Plan for Success the First Time (Have What You Need Before You Start)

What you don’t want to do is start on a project and then find out that you are missing what you need or don’t have enough veneer to finish the project.

Something that is very important to keep in mind is that different individual trees produce slightly different grain patterns in their wood – which means, for instance, that no two American walnut veneer sheets will have exactly the same grain orientation, color tone, and overall character.

That makes it imperative to buy as much as you need (and frankly, a little extra) the first time around. If you run out, it will be nearly impossible to match up the wood’s tone and grain again, even if you get more of the same cut of the same exact species.

It’s also important to be prepared with the right tools for the job. This will depend on the application but will include some of the following tools and accessories: adhesive, like contact cement; a heat source, like an iron, a scraping tool (can be purchased or improvised), a ruler, and trimming tools, such as a veneer trimmer or a knife with a sharp blade.

Again, if you have questions about what you need, ask before you start.

Shop a Reliable Veneer Supplier

Working with wood veneer, just like working with solid wood, requires special skills, tools, and most importantly, experience, which is equivalent to knowledge.

These are all reasons that you should shop with a reliable veneer supplier. They will have experienced staff on hand that can answer your questions about necessary tools and guide you through the process of application.

Shopping a reliable supplier that’s well-established in the industry also hedges your bets on the quality of the veneer you intend to purchase.

Learn As Much As You Can Before You Start

There are a lot of terms and jargon that wood veneer suppliers use that can be confusing, so it’s good to ask questions and read up on the craft before you take on a project.

For instance, learning about the differences between the appearances of different cuts can help you pick out panels and sheet that are matching – terms like “flat-sawn,” “quartersawn,” or “knotty,” “rustic” or “burl,” all connote different appearances in the wood grain.

Other terms, like sequence and end matching are also helpful to understand before beginning a project, as are the different types of backers that are applied to wood veneer.

Once more, this is an area in which you should ask for help from your supplier if you are confused.

Utilize Supplier Resources

Some sellers publish helpful educational and referential materials that can help you make better-informed decisions about what to purchase or what you’ll need, without having to call up a representative.

Suppliers like Oakwood Veneer also maintain dedicated databases of blogs, Tips & Info pages, and more, where there are videos, articles, info sheets, and diagrams that you can use to help you make informed decisions about what to buy, what materials and tools you will need for a project, and how to execute certain processes.

Use these resources where you can find them, they are invaluable, and they will save you time and money.