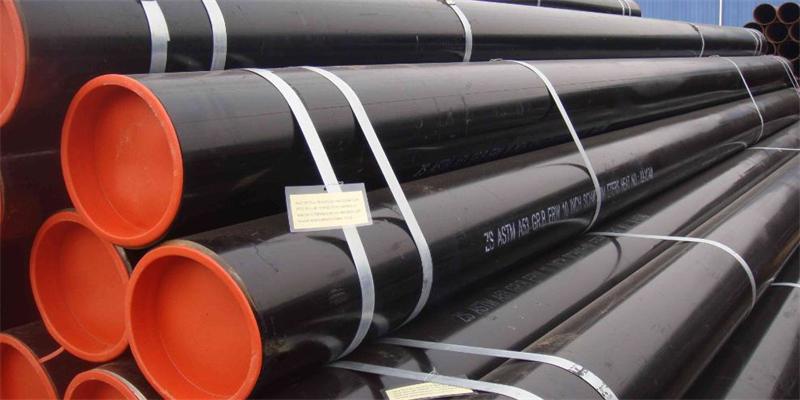

904L is a grade of stainless steel that manufacturers prefer to produce seamless piping solutions. It is a low-carbon steel that is also non-stabilized and austenitic. When manufacturers choose 904L steel grade to produce stainless steel seamless pipes, they add copper as an alloying metal. Copper enhances the properties of 904L steel.

Even though 904L steel is resistant to corrosion, adding copper makes it resistant to specific elements. Copper can tolerate acids better than steel. Hence, mixing copper with steel makes it more resistant to any acid, such as sulfuric acid.

Qualities of 904L steel:

904L steel is also resistant to corrosion caused by stress. For example, you do not have to worry about the steel pipes cracking or developing crevices if you expose the pipes to extreme pressure. The non-magnetic properties of stainless steel 904L make welding the metal much more manageable. Besides, the properties add to the strength and formability of the steel.

Manufacturers often enhance the quality of the 904L steel pipes by adding elements like nickel and molybdenum to the alloy. The melting point of molybdenum is relatively high. Hence, adding this element to the alloy gives the pipe fabricators more time to work with the alloy.

On the other hand, nickel is a great conductor of heat and electricity. In addition, it has a luster when you polish it. Hence, if the seamless pipe manufacturers want to build pipes that you can use for their thermal and electric conductivity, 904L steel with nickel is their ideal choice.

904L stainless steel pipes can also resist impact stress. As a result, you do not have to worry about chloride corrosion or pitting even when you use the pipes for a prolonged period in corrosive environments. If you are on a tight budget, choosing 904L stainless steel pipes and tubes can save you money. 904L steel pipes are much cheaper than nickel or titanium pipes. Hence, it has become a cost-effective option for many businesses.

Let us take a look at some of the benefits of 904L stainless steel.

The corrosion resistance of 904L steel:

When we say corrosion-resistant, what comes to your mind? You probably think that you can use the pipes for a long period without dealing with rusting. However, 904L stainless steel can withstand even more demanding environments. For instance, you can use these steel pipes under seawater and near marine environments. Neither will the pipes develop rust nor show any signs of corrosion caused by salt.

Similarly, you can use 904L stainless steel seamless pipes in and near swimming pools with chlorinated water. The chlorine in the water does not affect the longevity of the pipes. In addition, you can use these steel pipes in chemical plants, petrochemical industries, oil refineries, and other places. Even if the pipes are in constant contact with acids or other corrosive materials, they do not show any signs of erosion. Once you install 904L steel pipes, you can be sure they will last for years.

Heat resistance of 904L steel pipes:

Oxidation is one of the key reasons why most metal tubes and pipes start to develop signs of erosion. However, you do not need to worry about oxidation when you install 904L stainless steel pipes. As mentioned, nickel and molybdenum are crucial elements in the 904L stainless steel alloy. Nickel is resistant to oxidation. Therefore, you can use these pipes in high-temperature areas without noticing even the slightest sign of erosion. Besides, nickel can withstand extreme amounts of heat. If you do not use 904L steel, the pipes can break apart when they cross the threshold of 400° C. However, when you use 904L steel pipes with nickel, you can expose the pipes from 1090° C to 1175° C.

Seamless pipe suppliers use thermal treatment while processing the metal pipes. Hence, these pipes are suitable for extreme heat applications.

One of the major problems that many of you face is scaling and pitting of the pipes. If you invest in regular steel pipes, the problems will sustain. Instead, experts recommend that you choose 904L stainless steel pipes. As mentioned above, these pipes go through extensive treatments. Pipe providers not only heat the pipes to high temperatures but also use annealing to seal their strength. Annealing and cooling methods make a massive difference in the quality of the pipes.

Welding of 904L stainless steel pipes:

904L steel does not require any unique welding technique. Pipe fabricators use different conventional techniques to weld 904L steel pipes. Manufacturers do not need to pre-heat the 904L steel. In addition, manufacturers do not need to treat the pipes after heat treatment. If pipe fabricators follow constrained welding for 904L steel pipes, they can develop cracks.

Manufacturers must use filler materials while welding 904L steel pipes. If they fail to use filler materials, the pipes can show signs of poor strength.

Fabrication of 904L steel:

Seamless pipe suppliers choose 904L steel has low levels of sulfur. Hence, the quality of the steel is much better than conventional stainless steel. Pipe fabricators can use any standard method to machine these pipes. However, if you require the pipes to have a small radius, you should choose 904L steel pipes under cold conditions. Even though 904L steel does not require subsequent annealing, any experienced manufacturer prefers performing annealing. Annealing the pipes enhances their corrosion resistance properties and prevents them from cracking under stress.

Apart from producing seamless pipes, pipe fabricators often use 904L steel to produce overpowered machine equipment, sharp-edged tools, etc. However, pipe suppliers must use enough lubrication and maintain a slow speed when producing pipes and tubes from 904L steel.

Applications:

One of the major uses of 904L steel pipes is the chemical industry. The chemical processing plants work with abrasive and corrosive elements. Hence, it is vital for the industry to invest in a piping solution that can withstand the corrosive elements. You can also use 904L steel pipes in the petrochemical industry, food, and beverages, flue gas cleaning, bleaching, pulp and paper factory, pharmaceutical industry, boilers, heat exchangers, etc.

Since the seamless pipe manufacturers produce the pipes from 904L steel, you can use these pipes in seawater. For example, these pipes work great in shipbuilding, seawater handling, petroleum production system, fuel gas desulfurization, desalination, fuel-gas cleaning, etc.

Conclusion:

Whether you require 904L steel pipes or not will depend on multiple factors. Suppose you need pipes that you can use in highly corrosive environments, invest in 904L steel pipes. It becomes a more substantial component since manufacturers mix alloying materials, such as nickel and molybdenum, to 904L steel. You can use 904L steel pipes in shipbuilding, seawater handling, petroleum, oil and gas, and more.

The 904L pipes are resistant to abrasive materials, such as acids. Also, these pipes can withstand extreme pressure. Hence, you can use them in the petrochemical or oil and gas industries. Moreover, even when you expose the 904L stainless steel seamless pipes to extreme conditions for a prolonged period, it does not cause the pipes to develop scaling or pitting. Hence, most industries choose 904L steel pipes for their needs.