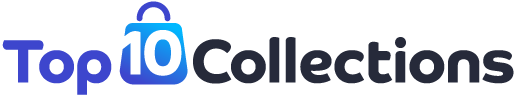

Regenerative braking and dynamic braking, two cutting-edge characteristics of the PowerFlex 523 AC drive, improve the performance and energy economy of motor-driven systems.

Regenerative Braking:

The PowerFlex 523 AC drive has a function called regenerative braking that enables it to store and redistribute energy produced during a motor’s slowdown or braking. The drive transforms this energy into usable electrical power, which can be sent back into the power supply system or utilised by other equipment in the plant, as opposed to dispersing it as heat.

Regenerative braking has several advantages, such as:

- Energy Savings: Regenerative braking greatly increases the energy efficiency of motor-driven systems by catching and recycling the energy that would otherwise be lost. Reduced energy use and operating expenses result from this.

- Increased System Efficiency: By reducing energy losses, regenerative braking maximises the overall effectiveness of the motor-driven system. Other motors or devices can be powered by the recovered energy, decreasing the need for additional power sources.

- Heat Reduction: Regenerative braking transforms extra energy into usable power rather than letting it escape as heat. This increases the longevity of the motor and other system components and lowers the possibility of overheating by keeping them cooler.

- Environmental Impact: Regenerative braking helps make operations more sustainable by collecting and reusing energy. This lowers the manufacturing facility’s carbon footprint and encourages eco-friendly practices.

The Rockwell Automation PowerFlex 523 AC drive must be properly configured and parameterized in order to use the regenerative braking capability. Setting up the brake resistors, modifying the braking torque control’s parameters, and configuring the feedback and control loops of the drive may all be necessary.

Dynamic Braking:

Another significant function offered by the PowerFlex 523 AC drive is dynamic braking. By dispersing surplus energy as heat, it helps a motor to decelerate quickly and under control. When stopping or decelerating needs to happen quickly and precisely, this capability comes in handy.

The main features and advantages of dynamic braking are as follows:

Precise Deceleration:

A motor’s deceleration can be precisely controlled via dynamic braking. In applications where exact positioning or controlled movement are crucial, it ensures smooth and accurate stopping, which is crucial.

The capacity to precisely manage and slow down the motor during the deceleration process is referred to as precise deceleration. It makes sure that the motor-driven system slows down or stops smoothly, enabling precision placement, controlled movement, and exact stopping at desired positions.

The PowerFlex 523 AC drive’s dynamic braking capability provides precise deceleration. With the help of this technology, the drive can release surplus energy as heat, resulting in regulated deceleration and avoiding abrupt stops or jolts that could harm the system and its parts.

Load Protection:

Dynamic braking aids in shielding the motor and other system parts from the potentially harmful consequences of abrupt deceleration. Dynamic braking eliminates mechanical stress and lowers the chance of equipment damage by dispersing the extra energy as heat.

- Mechanical Stress Reduction: The load may incur mechanical stress during acceleration, abrupt stops, or direction changes. The PowerFlex 523 AC drive has load protection systems that help reduce this stress by assuring regulated and smooth deceleration, preventing undue force or strain on the load and its components.

- Avoiding Product Damage: Load protection is essential in applications where the motor drives fragile or sensitive products, including in packing or handling procedures. The integrity and quality of the products are ensured by precise deceleration, which helps minimise product damage brought on by abrupt stops or excessive impact pressures.

- Equipment Longevity: The Allen Bradley PowerFlex 523 AC drive assists in extending the lifespan of the motor-driven system and its components by adopting load protection mechanisms. The mechanical parts experience less wear and tear due to the regulated deceleration, necessitating fewer repairs or replacements overall.

Enhanced Safety:

Dynamic braking enhances the overall safety of the motor-driven system by providing controlled deceleration. By assisting in the prevention of unplanned movements, stops, or reversals, accidents, collisions, or damage to the machinery and personnel are less likely to occur.

Heat Dissipation:

The extra energy created during deceleration is released as heat during dynamic braking. This promotes the longevity and dependability of the motor and other components by preventing the development of excessive heat.

It is crucial to configure and parameterize the PowerFlex 523 AC drive in order to use dynamic braking. To obtain the correct deceleration characteristics, this entails setting the proper brake settings, such as the deceleration rate and braking torque control.

Manufacturers may ensure accurate and controlled deceleration, safeguard their equipment, improve safety, and generally increase the efficiency and dependability of their motor-driven applications by utilizing dynamic braking in the PowerFlex 523 AC drive.

The PowerFlex 523 AC drive must be properly configured and parameterized in order to access these advanced functions. To ensure proper configuration and optimisation of the regenerative braking and dynamic braking functionalities, consult the drive’s literature or ask a professional for help.

We are Asteam Techno Solutions Pvt Ltd: the go-to company for industrial automation products. We make a contribution to the circular economy by providing all industrial automation products for businesses and factories and also providing service work for them. Through intensive collaboration with our customers and distributors, we prevent unnecessary investments and by extension, capital and material losses. Currently our staff members are serve a growing number of national and international customers each day.